High Pressure Die Casting

NovaCast high pressure die casting services produce geometrically complex castings, primarily from non-ferrous alloys such as aluminium and zinc. The production process allows thin walls to be created within castings that are strong and have excellent surface finishes. NovaCast high pressure die castings are used to produce a variety of components including pump housings and valve components.

The process

High pressure die casting (HPDC) can be divided into “cold-chamber” and “hot-chamber” processes. Hot chamber HPDC is used mainly with low melting point magnesium and zinc alloys whereas cold chamber HPDC is most commonly used with aluminium alloys.

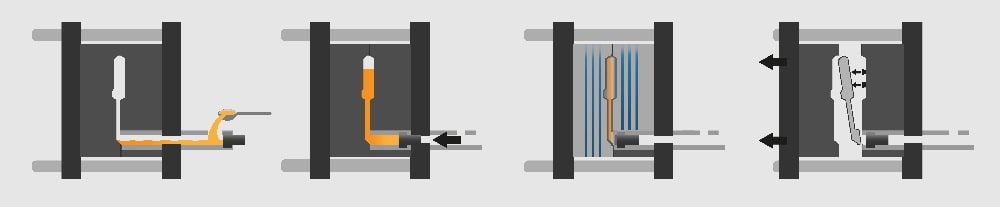

In the cold-chamber process:

- Molten metal is injected into a cold chamber for each machine cycle (or shot).

- The molten metal is forced by a single plunger through a narrow feeder channel (or gate), into the die cavity, by the application of pressures ranging from 1500 to 25,000psi.

- The die is water-cooled so the casting cools rapidly, usually within a fraction of a second, while pressure is maintained until solidification.

- Once solidified, the dies are opened and the casting is removed using ejector pins. Most castings will have flash where the two die halves come together, which is usually removed in a trimming die.

In the hot-chamber process:

- A gooseneck shot sleeve is submerged in a heated pot of molten melt.

- A plunger descends and forces the molten metal into the die.

- Once cooled, the casting is ejected by ejector pins.

- As the piston retracts, the cylinder is filled with metal and the process repeats.

Compare Gravity & Pressure Die Casting

An article on the differences between pressure and gravity die casting…

Why use NovaCast High Pressure Die Casting?

High pressure die casting delivers many benefits including:

- The capability of casting large quantities

- The ability to cast complex shapes quickly and accurately

- Castings are high strength

- Surface finishes can be exceptionally good

- Production rates are rapid

- Production lines are not labour intensive

- Scrap metal can be recycled

Limitations of the process:

There are some disadvantages to this process including:

- The need to trim components

- Equipment and tooling costs are high

- Die life is limited

- Lead times to set up production can be long

To discuss your requirements, call a member of NovaCast’s team on +44 (0) 1225 707466, send us a message here or email sales@novacast.co.uk.