Home » Services » Design Engineering » Reverse Engineering

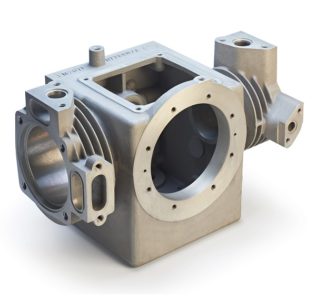

There are many reasons why a component may need to be reverse engineered. Unfortunately, in the modern world, foundries like NovaCast are often asked to take on castings where the original foundry has ceased trading and left a customer with a hole in its supply chain. Sometimes, the reverse engineering requirement is to take the existing physical dimensions of a component to then modify it to reduce weight, increase strength, etc.

Whatever the reason, NovaCast is able to replicate existing cast components using a variety of techniques from basic measuring and working up CAD files for basic geometries, to 3D scanning of complex components.

Download our Top 10 Tips for converting fabrications and assemblies to castings…

3D scanning and measurement can, however, only replicate the surface features of a component. For some, this may be all that is required but many complex components also have internal structures and elements that are integral to the function of the component. In this case, more advanced scanning techniques, such as X-Ray or other forms of penetrative radiation, are required if the component cannot be dis-assembled.

Whatever your requirement, the starting point is to contact our design engineering team to discuss the options available to you.

To discuss your requirements, call a member of NovaCast’s team on +44 (0) 1225 707466, send us a message here or email sales@novacast.co.uk.

Such is the importance of the relationship between the customer and foundry design engineering team, that we have restructured our internal systems to allow our design engineers to project manage castings from initial quotation and design development, through to overseeing the casting process and quality control prior to delivery.

Find out moreCasting Simulation Software provides an innovative and intuitive user interface allowing our design engineers to identify potential casting issues, such as air entrapment, porosity and cold shuts, thanks to a simple and quick mould filling simulation.

Find out moreNovaCast is at the forefront of the metal casting industry in employing 3D printing in the production of prototype patterns in its casting processes. The additive manufacturing process has become an important asset in recent years, particularly in rapid prototyping and short-run production of complex geometric shapes.

Find out moreSpaceClaim 3D Modelling software provides us a faster, more intuitive way of managing CAD files for casting geometry design, reverse engineering components and integrating a variety of source files into our production processes; helping us to arrive at the right design solutions faster.

Find out moreNon-Ferrous Alloy Specifications (Aluminium and Copper-based) When the NovaCast foundry was created in Melksham over 40 years...

Find out moreAluminium casting alloy LM25M (Standard Casting to BS 1490:1988 LM25) is a common general purpose alloy of aluminium which is...

Find out moreAluminium casting alloy LM25TF (Heat Treated Casting to BS 1490:1988 LM25TF) is a common general purpose alloy of aluminium which...

Find out moreAluminium casting alloy LM6M (Standard Casting to BS 1490:1988 LM6) has a high resistance to corrosion and excellent castability....

Find out moreAluminium bronze AB1 is an aluminium bronze conforming to the requirements of BS 1400. It has good strength and wear resistance...

Find out moreAluminium bronze AB2 is a nickel aluminium bronze conforming to the requirements of B.S. 1400 - 1985 alloy AB2. Suitable for...

Find out moreCarbon steel BS EN 10213:2007 (Gr 1.0619) castings used for pressure purposes are normally used in the annealed or normalised...

Find out moreCarbon Steel EN10293:2015 (G28Mn6 - 1.1165) is a ‘middle carbon steel' and one of the most widely used carbon steels in...

Find out moreOne of the most widely used carbon steels in the industry. Carbon steel SA216 WCB is used not only in many of the water- and...

Find out moreCarbon steel SA216 WCC is one of the most widely used carbon steels in industry. This material is used not only in many of the...

Find out moreCarbon steel SA352 LCC is one of the most widely used carbon steels in industry. Typically referred to as a cast low temp steel,...

Find out moreTo discuss your requirements, call a member of NovaCast's team on +44 (0) 1225 707466, send us a message here or email...

Find out moreGrey iron EN-GJL-200 is a type of cast iron that has a graphite microstructure. It is named after the grey colour of the fracture...

Find out moreGrey iron EN-GJL-250, or grey cast iron, is a type of cast iron that has a graphite microstructure. It is named after the grey...

Find out moreAustempered Ductile Iron or ADI is a heat-treated form of ductile iron that exhibits enhanced strength and toughness. Its...

Find out moreLeaded bronzes and gunmetals (also known as red brass) offer better machining characteristics than other bronzes while...

Find out moreLeaded bronzes and gunmetals offer better machining characteristics than other bronzes while maintaining a good balance of...

Find out morePhosphor bronzes have phosphor added to the alloy to improve strength and hardness. Phosphor bronze PB1 (BS 1400 1985 PB1) is a...

Find out morePhosphor bronze PB2 (BS 1400 1985 PB2) is a phosphor bronze with a higher tin content than PB1, which means it has excellent...

Find out moreSpheroidal graphite cast iron 420/12 (BS EN 1563:1997), also known as ductile cast iron, is a type of cast iron that has been...

Find out moreSpheroidal graphite cast iron 600/3(BS EN 1563:1997), also known as ductile cast iron, is a type of cast iron that has been...

Find out moreDuplex stainless steel 332C13 (BS 3100:1991)Â has a structure that is usually 40 to 50% ferrite with the balance of the...

Find out moreStainless steel SA-351 CF3 is the cast equivalent of type 304L stainless steel. CF8 and CF3 have very similar chemical and...

Find out moreStainless steel SA-351 CF3M is a molybdenum bearing modification of CF3 austenitic steel alloy and is the cast equivalent of...

Find out moreStainless steel SA-351 CF8 is the cast equivalent of Type 304 Stainless Steel, part of a range of austenitic chromium-nickel...

Find out moreStainless steel SA-351 CF8M is a molybdenum bearing modification of CF8 austenitic steel alloy and is the cast equivalent of...

Find out more