NovaCast takes significant steps towards renewable energy goals

At NovaCast, we are continually striving to enhance our sustainability practices, recognising the critical importance of environmental responsibility in today’s climate. In March 2024 we took significant steps towards using renewable energy by installing our first Solar Panels to our Head office in Melksham, UK. With sustainability at the forefront of our operations, we expanded...

NovaCast Enhances Precision with FARO Quantum XM Upgrade and CAM2 Training

In April 2025, NovaCast’s Dong, Engineering/Quality Manager, and Tom our Mechanical Engineer, attended a two-day training course at the Faro Centre in Rugby. During their time on the course, they acquired comprehensive expertise in CAM2, a 3D measurement software developed by FARO Technologies, recognised for its high precision and its ability to optimise and streamline...

NovaCast Achieves B Score in Carbon Disclosure Project, Demonstrating Commitment to Sustainability

NovaCast has improved its Carbon Disclosure Project (CDP) score from a D in 2023 to a B in 2024. This achievement reflects the company’s strong commitment to reducing its environmental footprint and contributing to global sustainability efforts. The Carbon Disclosure Project is an international non-profit that drives transparency and accountability around climate change, water security,...

Metal Passivation – what it is and how it is used in metal casting

Metal Passivation – what it is and how it is used in metal casting Passivation is a process used to protect metals against corrosion by creating a protective oxide layer on the surface of the metal. The objective is to shield reactive metals from damaging chemical reactions by creating an inert, or passive barrier between...

Converting fabricated wheels to castings frees up welding capacity

Supply Plus Limited designs, manufactures and distributes a range of high quality, professional safety and fuel delivery equipment, including a mobile hose reel that has the capacity to hold up to 200m of 70mm lay flat hose. The design incorporates two wheels that were formally fabricated in-house. Due to the success of the hose reel...

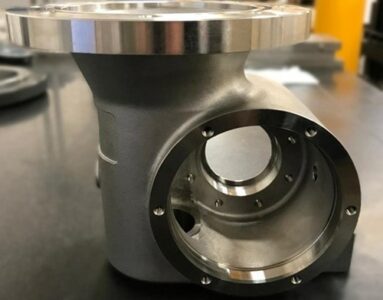

Gearbox Housing cast in CF8M

This 12KG investment cast stainless steel gear box housing has recently gone through our quality control department prior to shipping. It is cast in CF8M, which is the cast equivalent of wrought AISI 316 stainless steel. CF8M was selected for this casting because the molybdenum content in the alloy increases general corrosion resistance and resistance...

NovaCast continues engagement with CDP to improve sustainability

NovaCast has continued to demonstrate its commitment to environmental transparency by once again disclosing its environmental impact through CDP, the global non-profit that runs the world’s environmental disclosure system. Now with the world’s largest, most comprehensive dataset on environmental action, the insights that CDP holds empowers investors, companies, cities, and national and regional governments to...

The rise and rise of aluminium as a casting material

Aluminium is one of the most important raw materials used in metal casting due, in part, to its combination of versatility, relatively low weight, and high strength. It is used in castings across a wide range of industries from aerospace to automotive and electronics to renewable energy. At NovaCast aluminium is one of the primary...

Brinell hardness tester is both fast and accurate

NovaCast’s semi-automatic digital Brinell hardness tester uses a pressure sensor instead of traditional weights to perform Brinell hardness tests. The testing force and dwell time is set via a control panel. A digital Brinell microscope with adjustable LED illuminator automatically reads the indentation and instantly displays test results, making it both fast and extremely accurate....

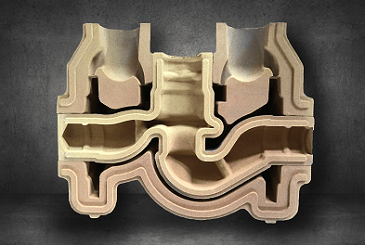

Norton Commando 850 Cylinder Barrels now cast by NovaCast

One of several OEM Norton Motorcycle components being manufactured by NovaCast. These Norton Commando 850 cylinder barrels are cast in BS1452 Grade 17 cast iron using the shell mould casting process then powder coated, machined and honed to original specifications. We are also producing complex wheel hubs with cast-in inserts and various other components for...

Casting Process Comparison: Sand Casting vs Shell Mould Casting

In this article we consider the differences and similarities between two closely related casting processes. Both use sand moulds to produce castings but the differences in the processes make them suited to quite different applications. Sand casting is one of the oldest casting processes dating back at least 5000 years. The simplicity and versatility of...

Constant refinement and improvement in motorsport

Working with motorsport manufacturers is a pleasure for our design engineers. There’s always a keen focus on engineering excellence, innovation and performance with pressure to refine the casting further each time. This bell housing for one of the UK’s leading race car manufacturers is sand cast in Aluminium casting alloy LM25TF (Heat Treated Casting to...

NovaCast adds to its sand core production facilities

Small but perfectly formed. Our new resin-sand mixing machine will improve both flexibility and efficiency at our Melksham foundry. The 1-Tonne per hour capacity may be small but it is the perfect solution for sand-core and small mould production, complementing the existing larger scale equipment on site.

NovaCast is working with Andover Norton to cast Norton spare parts

One of the most rewarding aspects of our business is having the opportunity to work on iconic British engineering heritage. We have started working with Andover Norton, the exclusive source of Norton motorcycle spare parts. This front wheel hub for a Norton Commando 750 is sand cast in LM25 aluminium with two cast-in elements; a...

New Casting Process Data Sheets

Following the recent re-launch of our website, we have continued to add new content and I wanted to point you in the direction of our data sheets. We now have over 30 on the site covering the technical specifications of all the main alloys that we cast. We have also recently added data sheets for...

NovaCast improves Ecovadis rating once again

Despite tougher Ecovadis scoring methodology, NovaCast has further improved its sustainability rating with the world’s largest and most trusted provider of business sustainability ratings. Following on from our silver medal in 2023, we have once again been awarded a silver medal that places us in the top 15% of the 130,000 companies Ecovadis assesses worldwide....

NovaCast and Xylem planting project for Noah’s Ark

Noah’s Ark Children’s Venture is a charity providing a residential facility for disadvantaged and disabled children at Macaroni Woods near Cirencester. Their aim is to make a positive difference to the lives of children and young people who are experiencing social or educational exclusion, by reason of their youth, disability, poverty, or social and economic...

NovaCast provides a new public access defibrillator at it’s Bowerhill office

It’s a sobering thought that approximately 95% of people who suffer a sudden cardiac arrest will die before they reach hospital. This figure could be transformed into a survival rate of 70% if more locally available defibrillators were in place. At NovaCast, we have been working with London Hearts, an organisation set up to help...

Metal shrinkage in castings and why it matters

Within this article, we take a look at one of the issues within metal casting that is critical to get right but challenging to understand, even for those within the industry...

Bringing a piece of British motoring heritage back to life

In the early 1900’s, British car manufacturers were at the forefront of motor vehicle development. The Vulcan Motor company, based in Southport, England, was one such innovator that produced cars from 1902 until the late 1920s. Today, early examples of Vulcan cars are extremely rare collectors’ items. NovaCast was approached by a specialist engineering company...

NovaCast’s stockholding capability protects customers from Red Sea shipping delays

NovaCast’s customer base is a healthy mix of those ordering from our UK foundry, and those that want to take advantage of the more competitive rates and capacity of our partner foundries in the Far East and India. Clearly, for castings imported from these international locations, the current disruption in the Red Sea could have...

Job Vacancy: Quality Technician

Due to the substantial growth of the business NovaCast is looking to recruit a full-time Quality Technician who will be based at our foundry in Melksham. This is an exciting opportunity to work within a growing business that is investing in the latest foundry technologies and systems. The full job description can be found here...

The Differences Between Non-destructive and Destructive Testing of Metal Castings

In a perfect world, every casting would be free of defects and perform exactly and reliably to design specifications. The reality, however, is that casting metal is a process subject to a multitude of factors that affect the way that an alloy reacts throughout the process. The inevitable result is that defects are an inherent...