Investment Casting

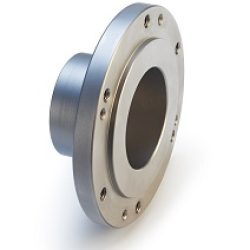

NovaCast has built a reputation for manufacturing high quality investment cast valve and pump components, primarily in carbon steel and stainless steel, including pressure tight valve and pump bodies, machined and balanced impellers and many other highly specified products. The investment casting process delivers high integrity castings that are dimensionally accurate, very versatile and have low repeat run costs. NovaCast has worked with several manufacturers to replace expensive fabrications with high quality investment cast components which are more cost effective, stronger and more aesthetically pleasing.

Selecting the right casting process for your project

Download our review of the main casting processes and how to choose…

Why use NovaCast Investment Casting?

Investment casting delivers many benefits including:

- Great versatility; suitable for casting most metals.

- Will allow very intricate castings to be produced.

- Smooth surface finishes are possible with no seam line so machining and finishing are reduced or eliminated.

- Allows un-machinable parts to be cast accurately instead.

- Excellent dimensional accuracy

- High volume production can be achieved with low repeat costs.

- Can be used to prototype and prove designs prior to die casting tooling investment.

- Is ideally suited to smaller, intricate or complex designs although we can cast up to 250kg

Investment Casting process

- A metal die is made, the impression being the same as required in the final mould.

Download the Investment Casting Process Data Sheet here - Molten wax is injected into the metal pattern, allowed to solidify and then removed. Some complex wax patterns are fabricated by joining several separate patterns together using an adhesive.

- The waxes are then assembled on a wax tree, many parts can be put on the tree depending on size, it is common for components to be in the weight range 0.1kg up to 80kg.

- The tree is then immersed in several different slurries to coat the wax, the initial slurry is fine as this will be the surface finish of the final casting.

- After drying, the trees of wax are put into ovens of about 200 degrees to melt out the wax.

- When all wax is removed the trees are heated up to about 900 degrees to complete preparation for casting.

- The metal is then poured into the moulds.

- Once solidified, the outer shell is broken away to reveal the finished casting.

Limitations of the process

There are some disadvantages to this process including:

- Preparation of the wax patterns and shell moulds is time consuming so can be expensive.

- Investment casting is not well suited to very high volume manufacturing due to the cycle times.

To discuss your requirements, call a member of NovaCast’s team on +44 (0) 1225 707466, send us a message here or email sales@novacast.co.uk.