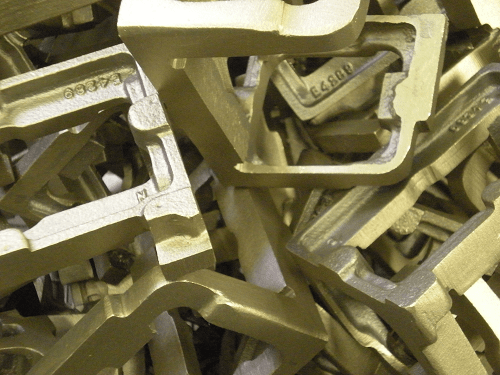

The use of Aluminium Bronze in Metal Casting is widespread as it is a remarkably versatile alloy, conforming to the requirements of BS1400, and created when Aluminium is added to Copper as the primary alloying element with smaller amounts of Nickel and Iron to boost corrosion-resistance. Various grades of Aluminium Bronze are available with the amount of Aluminium added determining the characteristics of each. The two most prevalent, and the ones used most often at NovaCast’s foundry, are AB1 and AB2. Although NovaCast primarily uses these alloys in the Sand Casting process, they are also used in shell, investment and die casting and are found extensively throughout the Marine, Oil & Gas, and Petrochemical industries.

Whichever Aluminium Bronze alloy is selected, they share some common attributes that demonstrate why this is such a useful alloy:

- Exceptional Strength: On a par with Mild Steel, Aluminium Bronze is the strongest and toughest of the Copper-based alloys with as-cast tensile strength of 500 to 590 Mpa. It also offers very good wear resistance, which can be further improved through heat treatment.

- Excellent corrosion resistance: It has excellent stress-corrosion and wear resistance, particularly in seawater and other Chloride-rich environments, due to the tough oxide film that forms over exposed surfaces as the alloy reacts to atmospheric Oxygen. In addition, Aluminium Bronze is biostatic which deters the growth of algae, barnacles and other marine life. For these reasons, Aluminium Bronze is used widely within the marine industry for propellers, valves, underwater fastenings, and for pump applications where impeller peripheral velocity is high (up to 45m/sec) as it resists cavitation erosion.

- Safety: Aluminium Bronze is often used within the Oil & Gas, Mining, Aerospace and Petrochemical industries where its non-sparking and corrosion resisting properties make it perfectly suited to environmentally aggressive applications where there is also a high risk of fire or explosion.

- Temperature tolerance: The Copper alloys are good for low-temperature applications as most of their physical attributes (the tensile properties, modulus of elasticity and fatigue strength) improve as temperature falls with no embrittlement, even down to the temperature of liquid helium. This property allows the Aluminium Bronzes to be used in many cryogenic applications, particularly valves for handling liquified gases.

- Magnetic Permeability: Aluminium Bronzes can be made with exceptionally low magnetic permeabilities and are ideal for non-magnetic instrumentation, mine-sweeper components and critical marine parts where permeability must not exceed 1.05. The magnetic permeability of certain aluminium bronzes is often less than 1.01.

- Tarnish Resistant: Aluminium Bronze is the most tarnish resistant of all the Copper alloys – the appearance of the material does not deteriorate when exposed to the effects of atmospheric corrosion making it an excellent choice where aesthetics is important.

Castability

Castability is generally good as Aluminium Bronze offers the advantage of a short freezing range which means that material properties remain consistent across widely varying section thicknesses. Careful handling in the foundry is needed, however, to avoid oxide inclusions and close attention must be paid to cooling rates.

Heat treatment of components cast in Aluminium Bronze increases their resistance to wear although care must be taken to avoid distortion. Stress introduced during machining or welding can be relieved with annealing which homogenises internal properties across heat-affected areas.

Conclusions

While any Copper-based alloy can be relatively expensive, the combination of attributes that Aluminium Bronze exhibits makes it an excellent choice where strength, durability and corrosion-resistance are important. If service life and maintenance costs are considered, particularly in harsh environments, the choice of Aluminium Bronze can make sound financial sense.

As specialists in the use of Aluminium Bronze in Metal Casting, NovaCast is happy to discuss your project requirements and the selection of the most appropriate alloy for your needs. You can find a wide range of alloy data sheets, including the Aluminium Bronzes, in the Alloy Specifications section of our website or call a member of NovaCast’s team on +44 (0) 1225 707466, send us a message or email sales@novacast.co.uk.