NovaCast: A single-source solution for both ferrous and non-ferrous castings

As any Design Engineer involved in the design for cast metal components will know, the selection of the metal alloy and casting process they will specify can be a complex process. Ultimately, for the Design Engineer, the specification must take account of parameters such as weight, yield strength, toughness, ductility, weldability, elasticity, shear, and thermal...

Heat Treatment of Castings

Heat treatment of castings is primarily used to alter the physical, and sometimes chemical, properties of the cast alloy. Many of the mechanical properties of both ferrous and non-ferrous alloys are determined by their microstructure. Heat treatment Is an efficient way of manipulating the crystalline structure of the alloy to modify its mechanical behaviour in...

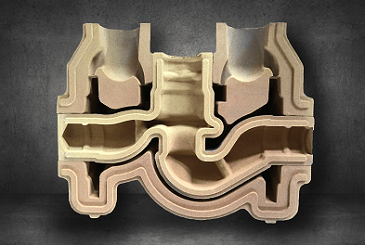

What is Shell Mould Casting?

At NovaCast, we offer a wide range of casting process options as each have strengths and weaknesses that make them suited to certain applications and alloy choices. Shell Mould Casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable sand-based mould. However, in Shell Mould Casting,...