Casting Process Simulation Complements Traditional Foundry Expertise

Casting Process Simulation is used by NovaCast to develop comprehensive modelling of the intended production process to determine the size and shape of sprues, runners, gates, and risers. One of the main benefits of these systems is that they make it possible for us to quickly identify areas within the casting geometry that could give...

The Importance of Parting Line Design in Gravity Die Cast Components

As part of our series of articles discussing various aspects of Gravity Die Casting, we are taking a look at the importance of parting line design. The parting line is where two or more sections of the Die split to release the casting. When deciding where to place the parting line, designers will need to...

The case for Sand Casting

The Sand Casting process has been a key element in manufacturing for thousands of years and still accounts for approximately 70% of all castings. Whether Sand Casting is the best option for the production of a particular component will be dictated by considerations such as the required geometry, performance, alloy choice, production run, tolerance within...

The case for Gravity Die Casting

There are many different casting processes and each has its place. The inherent characteristics of each make them ideal for a particular component geometry, performance requirement, alloy choice, production run or tolerance within specification. Gravity die or permanent mould castings use a Cast Iron or Steel mould consisting of at least two parts. The most...

NovaCast launches new company brochure

Download the NovaCast brochure “A Single Source Solution for Precision Cast and Machined Components” for an overview of our capabilities in Sand Casting, Gravity Die Casting and Investment Casting. Optimised for viewing on digital screens, our brochure will be updated regularly as we grow into new markets and introduce new technologies to our business.

Fabrication to Casting: Steam Trap re-design creates market leading solution

As specialists in the conversion of fabrications and assemblies to single cast components, NovaCast is cutting costs and improving efficiency for its customers. One such customer is EBE Engineering; manufacturers of an innovative Venturi Orifice Steam Trap. Originally a fabrication comprising a cast stainless steel body with two welded flanges; the steam trap was slow...

NovaCast shows its support for Wiltshire Air Ambulance

As well as making a donation of £1,000 for the Wiltshire Air Ambulance’s Airbase Appeal, NovaCast has pledged ongoing support by making monthly donations. NovaCast’s Sales Director, Richard Phillips, said: “Even though NovaCast is a business that trades internationally, we feel that we are part of the local Melksham community and want to contribute wherever...

Specifying the right cast Steel alloy

Cast Steel has become an increasingly important part of NovaCast’s business over recent years. The combination of excellent design, project management and quality assurance skills at our UK foundry with the low-cost, high-quality, high-capacity capabilities of our Far Eastern partners has allowed us to compete for and win many prestigious cast Steel projects. Although we...

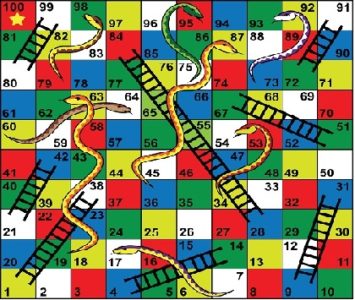

Brexit: Snakes and Ladders on an industrial scale

So here we are. Almost a year since Article 50 was invoked and the countdown to Brexit began. The political debate rumbles on and the media frenzy about the looming “cliff edge” if no deal is agreed is gathering pace. Against this backdrop it is easy to assume that the UK economy, and UK manufacturing...

Casting Design Considerations for Design Engineers

The design and manufacture of a metal component involves a multitude of decision points and will be influenced by considerations such as structural performance, weight, lead time, cost and aesthetics. It is understandable, therefore, that thoughts about how precisely that component is going to be manufactured are often left until the design is at a fairly...

Xylem and NovaCast join forces for Cotswold conservation project

Richard and Lauren Phillips and Richard Chandler of NovaCast recently joined employees of Godwin Pumps to support a Xylem Watermark conservation project at Abbey Grounds in Cirencester...

NovaCast strengthens its Gravity Casting Capability

Richard Chandler, formally Production Manager at NovaCast, is taking on a the newly created role of Technical Sales Manager at the company’s Melksham Head Office. During a difficult few years for the UK metal casting industry, NovaCast has continued to prosper, largely due to its outward-looking approach to world markets and its willingness to invest in people, technology and infrastructure within its Melksham Foundry...

Top 10 Design Tips for Problem Free Gravity Die Casting

Gravity Die Casting (also known as Permanent Mould Casting) is a repeatable process primarily used to produce medium-run, dimensionally accurate, non-ferrous castings, most often in alloys of Aluminium, Zinc and Bronze. Here are the Top 10 Tips for designing problem-free casting geometry…

Top 10 Tips for switching fabrications and assemblies to castings

There are many reasons why a manufacturer may choose to substitute complex fabrications, weldments and assemblies for castings. Here are the top 10 tips for selecting suitable candidates for conversion.

NovaCast is delighted to announce that our new website is up and running

After months of hard work, our fully re-developed website is here. It’s a comprehensive information resource covering casting techniques, metal specifications and casting capacities but just as important, it is also a window on our business. It’s a way to get to know us and the way we do things both at our Melksham Foundry...

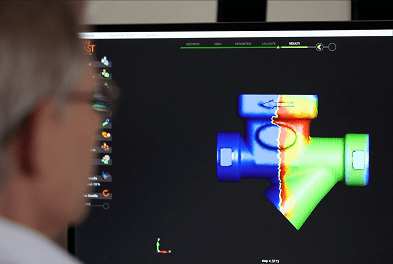

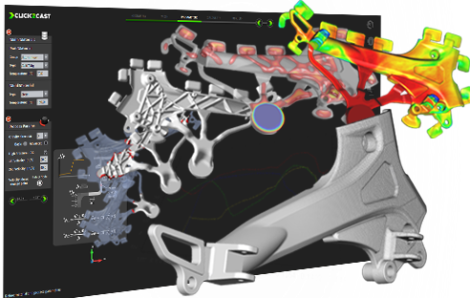

NovaCast invests in casting process simulation software

Following on from the acquisition of new 3D modelling software, and as part of our programme of continual improvement, NovaCast is investing in Click2Cast casting simulation software. The innovative and intuitive user interface will allow our engineers to identify potential casting issues, such as air entrapment, porosity and cold shuts, thanks to a simple and...

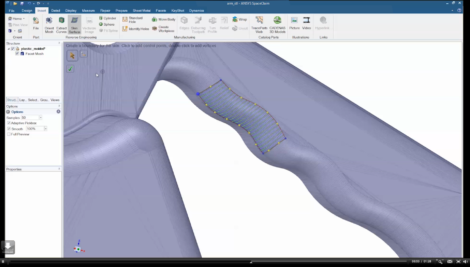

NovaCast upgrades its 3D Modelling Software

At NovaCast we are continually investing in technology that will benefit our customers and improve the service we are able to provide. Although we have worked with CAD for many years, we have recently upgraded our in-house system to SpaceClaim 3D Modelling software. This provides us a faster, more intuitive way of managing CAD files...

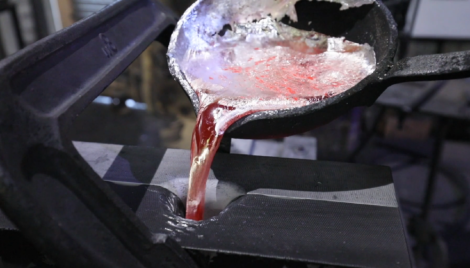

Sand Casting Foundry: Where tradition meets technology

Sand casting is a traditional process dating back many thousands of years, but components produced using this process are still an essential part of our lives today. In this article we outline the sand casting process as carried out in a modern sand casting foundry, where technology and tradition are combined. Although it dates back...