Rapid Prototyping: How 3D Printing is making its presence felt in the foundry

As a long-established foundry with its roots in sand and gravity die casting, NovaCast has grown and evolved over the years to become a modern, diverse and international foundry, with customers and production partners around the world. As the business has developed, it has embraced new casting processes, such as investment casting, lost foam casting,...

Analysis and Testing of Metals: The use of Spectrometers in foundries

Over the years, technology has played an increasingly important role in metal casting foundries. NovaCast, for example, uses the latest Casting Simulation Software, 3D Modelling and 3D printing to streamline processes, raise productivity and improve quality. One such area where technology is used to great effect in foundries is the use of Spectrochemical analysis for...

The Main Alloying Elements used in Cast Stainless Steels

When considering the alloy specification for a cast Stainless Steel component, it is critical that the service environment in which the cast component will be deployed is taken into account. The chemical composition of the Stainless Steel alloy will determine its performance characteristics and suitability for each application. At NovaCast, we supply a wide variety...

NovaCast shows the way to a greener, more sustainable industry

Over the years the metal casting industry has acquired a reputation as one of the worst in terms of environmental impact, largely due to traditional production practices with high energy usage going in and highly toxic emissions coming out. Add to this the massive energy demands for the extraction and production of raw metals, such...

NovaCast signs up to the WASH Pledge

The COVID-19 pandemic is a stark reminder that whoever you are and wherever you live, one of the most effective ways to stop the spread of a virus or other pathogens is also one of the simplest: hand hygiene, especially through handwashing with soap. For many of us, hand hygiene is as simple as remembering...

Brave Blue World Documentary

At NovaCast, we have always supported charities and initiatives set up to address the global water crisis, such as the Planet Water Foundation and Xylem Watermark. That’s why we are delighted to help promote an important new documentary produced by the Brave Blue World Foundation, narrated by Liam Neeson and featuring Matt Damon and Jadon...

The Use of Fluxes in Aluminium Casting

At NovaCast, a large proportion of our castings are produced using Aluminium alloy. The formation of Aluminium Oxide and the presence of non-metallic inclusions, collectively known as dross, is an inherent part of the casting process and one that must be managed to achieve the highest quality castings. For many years, part of the foundryman’s...

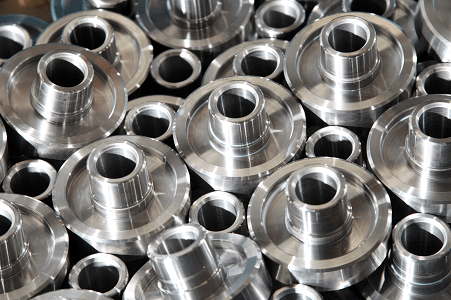

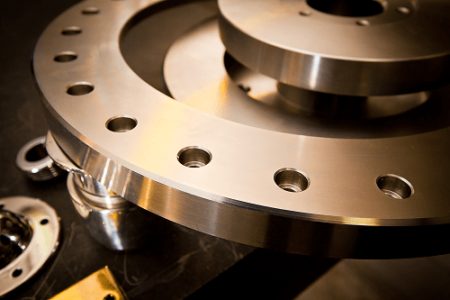

Impeller Casting Specialists

The accurate casting and balancing of impellers requires a specialist set of skills as well as a commitment to outstanding consistency and quality. For many years, NovaCast has cast and machined impellers and pump components for a wide variety of industries and applications ranging from centrifugal pumps used in the Oil & Gas, Chemical, Water...

Quality Assurance Technician Required

Following re-organisation and expansion of our engineering department, we have an immediate requirement for a Quality Assurance Technician to join the department. Reporting directly to our Design Engineer, the successful candidate will work closely with our design and engineering teams, as well as those of our customers and suppliers, to maintain the excellent quality standards...

NovaCast achieves UKAS accredited ISO9001:2015 Certification

As part of its ongoing programme of investment in the infrastructure of the business, the management team at NovaCast has been determined to drive up quality standards and expand the capabilities of the business to allow it to compete with the best foundries in the world. When its ISO9001 certification needed to be renewed, there...

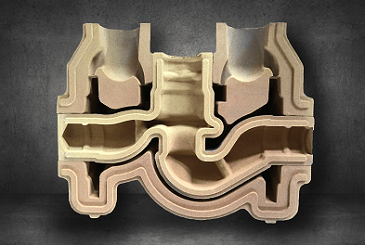

The differences between Lost Foam Casting and Lost Wax Casting

In many respects, the process involved in these two investment casting methods is similar. In both cases, a sacrificial pattern is made. In lost wax casting, this is made from a tooled mould and in lost foam casting, it may be made from a mould or carved from a solid block of foam material. A...

All change at NovaCast as Barry Hayward retires and new faces join the team

Following a period of sustained growth, with new business growing strongly and consolidation of existing contracts, NovaCast is looking to the future with confidence. During the past few months a transformation has occurred that has seen the re-organisation of the business, the opening of new offices at its Bowerhill site, investment in the Melksham foundry...

NovaCast team complete Tough Mudder for charity

Billed as “Probably the Toughest Event on the Planet”, Tough Mudder is a uniquely challenging obstacle course that requires endurance, fitness, determination to succeed and a love of mud! So, when Richard Phillips, Sales Director at NovaCast, was looking for events to boost the coffers of the company’s chosen charity, Wiltshire Air Ambulance, the...

The Difference Between Gravity and Pressure Die Casting

Die casting is one of the most widely used casting processes but what is the difference between Gravity Die Casting and Pressure Die Casting? Both are casting processes used by NovaCast, so we are well placed to explain the differences and discuss the selection criteria. Both forms of Die Casting employ a metal mould into...

Heat Treatment of Castings

Heat treatment of castings is primarily used to alter the physical, and sometimes chemical, properties of the cast alloy. Many of the mechanical properties of both ferrous and non-ferrous alloys are determined by their microstructure. Heat treatment Is an efficient way of manipulating the crystalline structure of the alloy to modify its mechanical behaviour in...

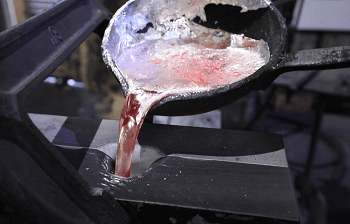

Elements of a Sand Casting Running System

The gating system includes all those elements which connect the pouring ladle to the mould. The various elements include: Pouring Basin or cup, Sprue, Sprue Base Well, Runner, Runner Extension, In-gate and Riser. An effective gating system should: Fill the mould cavity completely before the metal starts to solidify Control the speed that metal enters...

Focus on Metal Surface Treatments

NovaCast routinely uses a wide range of metal surface treatments on its cast products to enhance their mechanical, electrical or aesthetic properties. Surface treatments and finishes are often applied following surface preparation, usually in the form of fettling, linishing or shot blasting, and any final machining. Here, we focus on the surface treatments most commonly...

Aluminium Bronze in Metal Casting

The use of Aluminium Bronze in Metal Casting is widespread as it is a remarkably versatile alloy, conforming to the requirements of BS1400, and created when Aluminium is added to Copper as the primary alloying element with smaller amounts of Nickel and Iron to boost corrosion-resistance. Various grades of Aluminium Bronze are available with the...

What is Shell Mould Casting?

At NovaCast, we offer a wide range of casting process options as each have strengths and weaknesses that make them suited to certain applications and alloy choices. Shell Mould Casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable sand-based mould. However, in Shell Mould Casting,...

Types of shrinkage inherent in the casting process

We often say that casting molten metal is like handling a living thing. Understanding how different alloys will react to different casting processes, component geometry, running systems, temperatures, etc. is part of the art of the foundry engineer. In recent years, the wealth of experience built up at the NovaCast Foundry has been enhanced by...

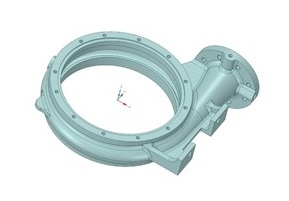

Engagement with Xylem’s VA/VE Programme delivers improved castings

Xylem, one of the leading global water technology companies, is committed to an ongoing process of product improvement and cost reduction. It does this, in part, through a Value Assessment and Value Engineering (VA/VE) programme in which it challenges its international supply chain to refine and improve every aspect of what they deliver. As...

NovaCast Donates $2,000 to the Planet Water Foundation

NovaCast is committed to supporting causes that enhance quality of life in communities around the world, particularly those where interventions can save lives. Having long been a supporter of Xylem Watermark, NovaCast has recently donated $2,000 to the Planet Water Foundation, one of their partner non-profit organisations. The Planet Water Foundation is a US based,...

NovaCast Invited to Join Wiltshire Air Ambulance 100 Club

In recognition of its ongoing support for Wiltshire Air Ambulance, NovaCast has been invited to become an honorary member of the 100 Club, the elite club for businesses pledging larger sums. In addition to the monthly contribution by NovaCast, staff members, led by Sales Director Richard Phillips, have already completed sponsored events to raise money for...

Non-Destructive Testing of Cast Components

The production of high-quality castings has always been a mix of sound design, technical knowledge and the foundryman’s experience in handling and managing each stage in the casting process. More recent innovations, such as casting simulation software and 3D modelling, have helped to reduce casting defects by improving both product and gating system design. Dealing...